Ecocycle MBR mobile wwtp system is a highly effective biological treatment process based on a combination of conventional activated sludge process and membrane bioreactor.

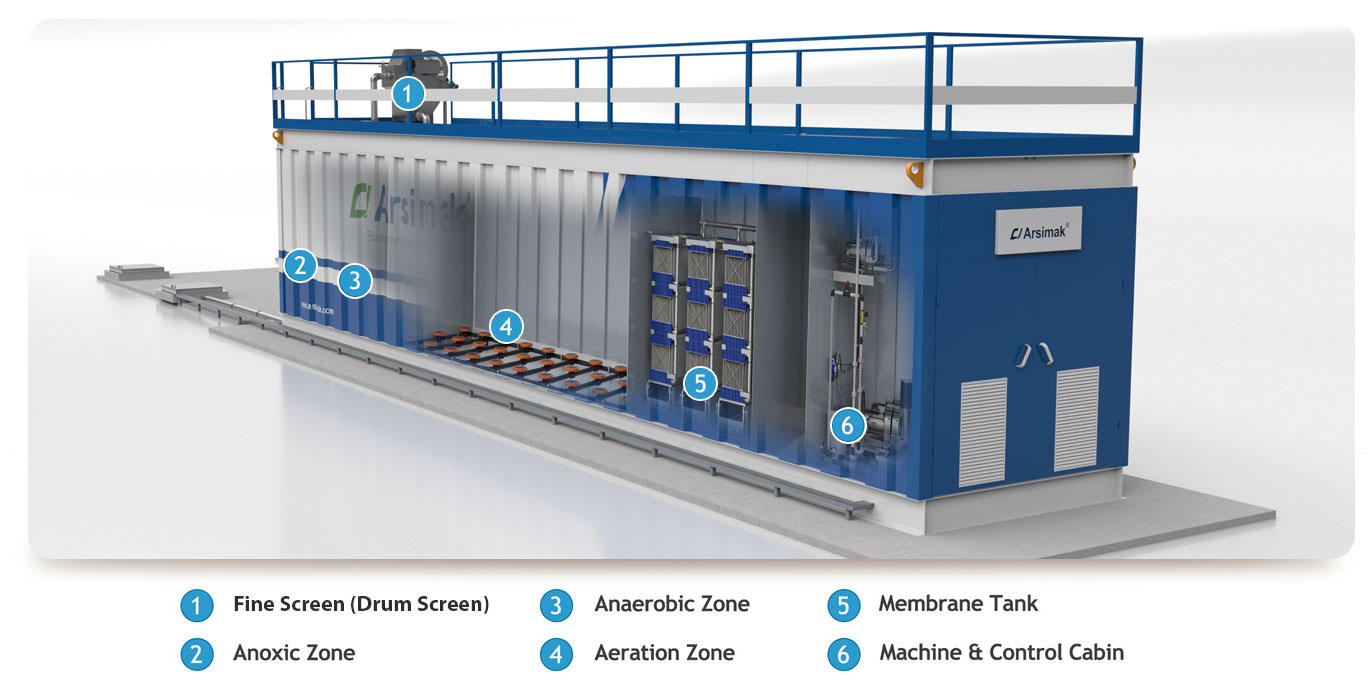

Ecocycle MBR Membrane Bioreactor contains all necessary stages, such as physical treatment ( primary treatment), anoxic chamber, aeration, clarification, disinfection, sludge storage section and all the mechanical - electrical equipments, piping, and instrumentation inside its compact structure as a mobile system.

- Automatic Screw Screen

- Chemical dosing systems

- Anoxic, anaerobic and aerobic tanks for biological treatment

- Air blowers for the aeration process and for membrane scouring

- Pump set for the MBR permeate suction and for sludge recirculation

- Cleaning tank for periodic chemical enhanced backwash of the MBR membranes

Ecocycle MBR provides easy installation and operation.

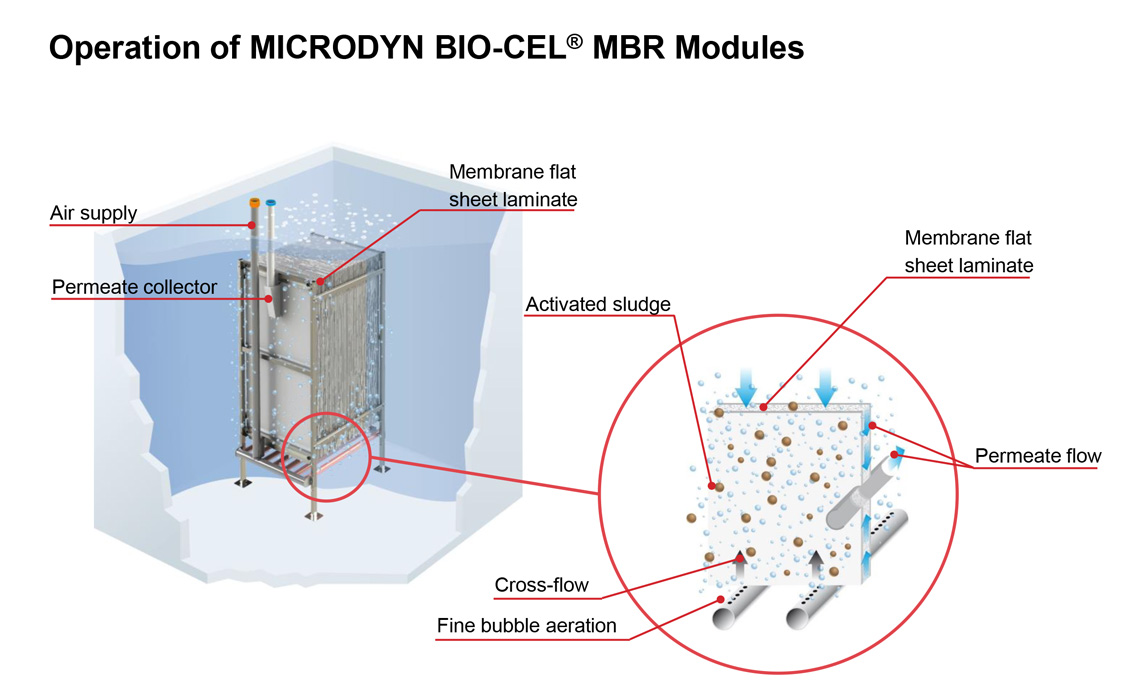

In a membrane bio-reactor (MBR) system, the biomass treats polluted water, while the membrane ensures the safe separation of the biomass from the cleaned wastewater. Traditionally, this separation process relied on solids settling in a secondary clarifier. In addition to better effluent quality, MBR Unit have the advantage to be operated with much higher MLSS (Mixed Liquor Suspended Solids) levels. Thus, an MBR plant requires less space than a conventional plant.

Ecocycle MBR provides easy installation and operation.

In a membrane bio-reactor (MBR) system, the biomass treats polluted water, while the membrane ensures the safe separation of the biomass from the cleaned wastewater. Traditionally, this separation process relied on solids settling in a secondary clarifier. In addition to better effluent quality, MBR Unit have the advantage to be operated with much higher MLSS (Mixed Liquor Suspended Solids) levels. Thus, an MBR plant requires less space than a conventional plant.

The key elements of an MBR system are the membrane and the aeration. The membrane serves as a physical barrier for the retention of solids and bacteria. The aeration generates the cross-flow which transports the mixed liquor along the membrane surface. This cross-flow prevents the accumulation of sludge on the membrane surface, resulting in a consistent and reliable operation.

Containerised MBR Solutions

- Screening

- Anoxic Zone

- Anaerobic Zone

- Aeration Zone

- Membrane Tank

- Machine - Control Cabin

Compact treatment units - plants are covered under service and maintenance warranty. Our company provides replacement parts and technical service for the subsequent years.

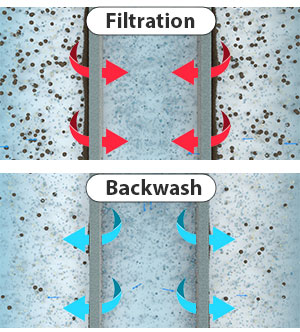

During the filtration, Activated sludge accumulates on the membrane surface as the treated water is sent to the permeate tank.

Some of this solid accumulation on the membrane surface is reduced with the help of air from diffusers located under the membrane modules.

Membrane Backwash:

Backwashing means a short period of time (20-30 seconds) during which the permeate flow is reversed through the membrane so that the permeate flows from the inside to the outside of the membranes.

During the backwash, the aeration of the membrane tank continues, with the air from the diffusers and the water returned from the permeate tank cleaning the membrane surfaces.

Advantages of Ecocycle® MBR Membrane Bioreactor Systems

- High Treatment Efficiency: MBR Membran Bioreactor produce high-quality effluent, meeting stringent discharge standards.

- Compact Footprint: MBR systems require less space than conventional treatment plants.

- Reduced Sludge Production: MBR generate less sludge, simplifying waste management.

- Energy Efficiency: MBR operate efficiently, consuming less energy than traditional methods.

- Sustainability: MBR contribute to water conservation and reuse.

What are the benefits of the Ecocycle® MBR biological container system treatment?

That's why Ecocycle® MBR WWTP solutions are the best choice for a low-cost, automated and reliable wastewater treatment plant.

- Ease of operation

- Modular design allows expansion

- Quick installation and start up

- Low operating expenditure

- Small footprint

- Low energy consumption

- Discharge quality to environmental standards

- Fully automated

Is it suitable for overseas loading?

Are components and spare parts easy to supply? (OEM)

Does Arsimak provide After Sales Support ?

Request A Quote.